Induction heating is a fast, precise, and Flameless® method of heating electrically conductive materials using electromagnetic fields. It’s transforming how professionals in automotive, agriculture, marine, and manufacturing industries perform heating-related tasks, eliminating the risks and inefficiencies of open flame methods.

Whether you’re loosening a rusted bolt or heating a metal panel, induction heating tools like the Mini-Ductor® and Inductor® Pro-Max offer unmatched control, safety, and speed.

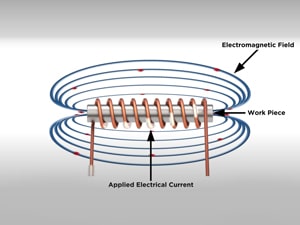

How Induction Heating Works

Induction heating works by generating electromagnetic fields that create heat directly within metal parts, without physical contact or flame. This makes it ideal for applications that require precision, speed, and safety.

In short:

- Alternating current flows through a coil

- This generates a magnetic field

- The field induces eddy currents in the metal, which heat from within

Read our in-depth guide on how induction heating technology works to explore the science behind it.

Key Benefits of Induction Heating

Induction heating is a smarter, safer, and more efficient way to apply heat in industrial, automotive, and repair settings. Unlike traditional methods that rely on open flames or direct contact, induction heating offers a range of advantages that improve performance while reducing risk. Here are the core benefits that make it a go-to solution for professionals.

Advantages of induction heating over conventional heating methods:

- Speed: Heats metal in seconds, not minutes.

- Safety: No flame means reduced fire risk.

- Precision: Heats only the targeted metal area, protecting surrounding materials.

- Efficiency: Converts up to 90% of energy into usable heat.

- Eco-Friendly: No emissions, no fuel combustion.

Tools like the Mini-Ductor® Venom HP apply these benefits in real-world applications like bolt removal, decal stripping, or loosening rusted parts.

Induction Heating vs. Traditional Heating

When evaluating heating methods for industrial or repair tasks, it’s important to understand how induction heating stacks up against traditional flame-based options. The table below highlights the key differences in efficiency, safety, precision, and environmental impact, showing why more professionals are turning to Flameless® solutions like induction tools.

| Feature | Induction Heating | Traditional Heating |

| Efficiency | High (up to 90%) | Moderate to low |

| Safety | Flameless® | Open flame, high risk |

| Heat Transfer | Internal, precise | External, uncontrolled |

| Environmental | No emissions | Fossil fuel combustion |

| Speed | Instant heating | Slow ramp-up |

Induction tools like the Pro-Max bring industrial-grade power without the hazards of torches or heat guns.

Where is Induction Heating Used?

Induction heating is a versatile solution used across a wide range of industries and applications where precision, safety, and efficiency are critical. From automotive repair to heavy equipment maintenance, its flameless performance makes it ideal for environments where traditional heating methods pose risks or limitations. Here are some of the most common and impactful use cases.

Induction heating is widely used across industries:

- Automotive: Rusted bolt removal, fastener loosening, glass/rubber seal removal.

- Farming: Repairing metal implements, fast maintenance in the field.

- Manufacturing: Brazing, shrink fitting, metal hardening.

- Marine: Spark-free heat in confined, flammable environments.

Products like the Mini-Ductor® Series are indispensable for technicians who need compact, handheld, high-performance tools.

Tools That Use Induction Heating

Induction heating technology comes to life through specialized tools designed to deliver targeted, Flameless® heat with maximum control. Whether you’re working in a tight engine bay or tackling heavy-duty shop repairs, the right tool makes all the difference. Below are key products that harness induction heating to solve real-world problems quickly, safely, and efficiently.

Explore some of the most trusted tools built around induction heating:

Mini-Ductor® Series

- Compact, handheld Flameless® tools

- Ideal for bolt/nut removal, decals, adhesives

- Explore Mini-Ductor® Models

Pro-Max®

- High-powered, shop-grade solution

- Handles larger metal surfaces, deep-seated parts

- Explore Pro-Max®

Coil Kits

- Range of coils for various fastener sizes and access needs

- Explore Coil Kits

Why Choose Induction Innovations®?

As pioneers in portable induction heating, Induction Innovations® delivers solutions trusted by thousands of technicians worldwide. Our patented Flameless® technology eliminates the guesswork and risks of traditional methods, ensuring speed, safety, and confidence on every job.

- Proudly made in the USA

- Over two decades of innovation

- Used in shops, farms, factories, and fleets

Learn more about Induction Innovations and our 20+ years of heating innovation.

Explore our complete induction-heating product line.

Still deciding if induction heating is right for your job?

The Mini-Ductor® and Inductor® Pro-Max continually deliver a safer, faster, smarter solution. Contact us today and see why Induction Innovations could be the right choice for you.

FAQs About Induction Heating

- What metals can be heated?

- Steel, iron, copper, aluminum, and other conductive metals.

- Is it safe?

- Yes. There’s no open flame, so it significantly reduces fire and injury risks.

- How hot does it get?

- Depending on the coil and material, induction tools can heat parts to a 200–300 °F temperature differential sufficient for most applications. Overheating beyond what is necessary should be avoided.

- Can I use it on aluminum?

- Yes, though it requires higher frequencies due to aluminum’s conductivity.

- Is training needed?

- Basic safety guidance is recommended, but tools like Mini-Ductor® are designed for intuitive use.