Induction heating technology is transforming industries by providing fast, efficient, and precise heating solutions. Whether you’re asking: “How does induction heating work?” or “What is induction heating?” our guide will break it down in simple terms. Induction heating uses electromagnetic fields to generate heat directly within metal objects, eliminating the need for open flames or direct contact.

At Induction Innovations, we’ve harnessed this technology in tools like the Inductor® Series and Mini-Ductor® Series, making it easier than ever for automotive, industrial, and maintenance professionals to safely and efficiently remove seized parts or apply heat exactly where it’s needed.

What is Induction Heating?

Induction heating is a process that uses electromagnetic fields to heat conductive materials, primarily metals. Unlike conventional heating methods, which rely on direct contact or flame exposure, induction heating generates heat internally within the material.

Key characteristics:

- Uses electromagnetic induction to produce heat

- Requires a conductive material such as iron, steel, or copper

- Provides precise, localized heating

- Eliminates the need for fuel-based heat sources

Featured Tool Example: The Inductor® Series is designed for high-powered, shop-grade applications like graphics removal and frame straightening using this very principle.

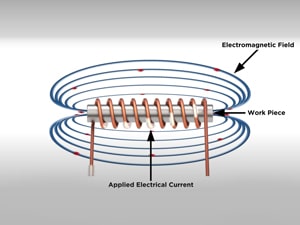

How Does Induction Heating Work?

The induction heating process involves:

- An electromagnetic induction coil is placed around or near the metal object.

- High frequency alternating current (AC) flows through the coil, creating an electromagnetic field.

- This field induces electrical currents (eddy currents) within the metal.

- The resistance of the metal to these currents generates internal heat.

Featured Tool Example: The Mini-Ductor® Venom HP features a patented flameless heating design that uses these principles to release rusted bolts and nuts in seconds, all without damaging surrounding components.

Key Benefits of Induction Heating

Induction heating offers several advantages over traditional heating methods:

- Energy Efficiency converts electrical energy into heat with minimal waste.

- Precision allows for targeted temperature control through localized heating.

- Speed heats materials significantly faster than conventional methods.

- Safety reduces workplace hazards by eliminating open flames.

- Eco-Friendly produces no emissions or combustion byproducts.

The Inductor Pro-Max is ideal for high-volume body shops that need speed and precision, especially in tasks such as removing adhesives, decals, or glass.

Expanded Applications

Induction heating is used across multiple industries for various applications:

- Automotive applications remove rusted bolts, heat bearings, and treat metal with Flameless® heat—ideal for field repairs on combines and farm equipment, as well as collision shop work where precision and safety matter.

- Manufacturing uses include hardening, brazing, and soldering metal components.

- Agriculture applications involve removing rusted bolts, bearings, and seized parts from combines and other heavy-duty farming equipment with precision — even in the field — using Flameless® heat for safe, controlled results without the risks of an open flame.

- Marine & Boat Repair uses incorporate freeing corroded components or applying heat without open flame in environments where safety and precision are critical.

Need to heat around corners or reach tight spots? Explore our full range of coil kits and coils designed for the Mini-Ductor® Series, perfect for tough-to-access areas.

By leveraging induction heating, industries can improve efficiency and reduce energy consumption.

Induction Heating vs. Traditional Heating Methods

| Feature | Induction Heating | Traditional Heating (Flame, Resistance, Oven) |

| Efficiency | High (Minimal Heat Loss) | Moderate to Low (Heat Dissipation) |

| Speed | Instant Heat Generation | Slower Heat Transfer |

| Precision | High (Localized Heating) | Low (Heat Spreads to Surroundings) |

| Safety | No Open Flames, Lower Risk | Fire Hazard, Direct Contact Required |

| Environmental Impact | Low (No Emissions) | Higher (Fuel-Based Combustion) |

Common Questions About Induction Heating

Q: How efficient is induction heating? Induction heating boasts an efficiency of up to 90%, significantly reducing energy waste compared to conventional methods.

Q: How hot does induction heating get? Our products are designed to rapidly and precisely bring ferrous materials to their Curie point, enabling efficient, controlled heating without an open flame.

Q: Is induction heating safe? Yes! Since it doesn’t require open flames or direct metal contact, it’s much safer than traditional heating methods.

Watch The Video:

Contact Us:

Since 2000 Induction Innovations, Inc. has helped customers enjoy the advantages of turning to induction heat for their project applications to save time, resources, and money. Talk with us about your industry needs and secure the perfect product for your requirements. Reach out to us via phone at 877-688-9633 or email at [email protected].

Follow us on social media: Facebook • Instagram • LinkedIn • TikTok • YouTube