Your cart is currently empty!

Have you ever needed to bend a wrench to fit a specific workspace? Or have you needed to form or shape metal to produce other custom tools?

Have you ever needed to bend a wrench to fit a specific workspace? Or have you needed to form or shape metal to produce other custom tools?

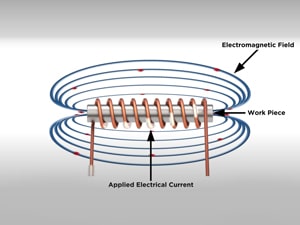

Instead of using a torch to heat the metal, use magnetic induction heat from Induction Innovations. This process is made easy with our wide variety of products ranging in power from 1000 watts to 5000+ watts.

How to Bend and Shape Metal

First, make sure that the metal you are heating is ferrous. Then, select the power you need to match the metal you are forming. Remember, varying thicknesses will require more power. Apply the magnetic field by powering the unit and heat to the desired temperature to achieve a malleable/softened state. Then shape or bend the metal as desired.

You can create drying hooks, racks, retail displays, frames, or even works of art! There are a wide variety of things you can do with induction heat.

Create Custom Tools:

Here are a couple of examples of customers using induction heat to form metal with the Mini-Ductor® Product line.

Real Tool Reviews

Real Tool Reviews on YouTube reviewed the Mini-Ductor II back in 2015. They used it to demo a few different applications, one of them being creating a custom wrench.

In this video, he took a standard wrench and put it in a vise. He used the Mini-Ductor to heat the middle of the wrench for about 10-15 seconds. Then he took pliers and easily bent the wrench to a 90-degree angle.

Click here to watch their custom tool demo, starting at 8:11:

Shop Tool Reviews

Next up, we have the Shop Tool Reviews Instagram that put out a quick demo on Instagram Reels.

In the video, they take a piece of PVC tubing and put a metal screw inside it. They then take the Mini-Ductor Venom and heat the tubing for a few seconds. The Mini-Ductor heats the metal screw on the inside that gives off residual heat to the tube. So once they take the screw out, they are able to use that residual heat and bend the tube to an angled position.

To ensure that the tube didn’t overheat or break, they sprayed it down with water afterward.

Watch that video here: Shop Tool Reviews

Create Custom Art Pieces:

Knox Forge Trail

For the fans of blacksmithing and custom hand-made home goods, check out this video from @knoxforgetrail on Instagram!

In this video, he uses the Mini-Ductor II to heat the middle of a metal rod to a red-hot temperature. He then grips it and gives it a couple of twists to form a twisted pattern in the metal. Going off of his website and Instagram, we can gather that he does this for artistic purposes or as part of the products he then forges by hand.

Create Custom Display Frames:

This last example is a video that we shot at the Induction Innovations offices. Here our sales manager, Mark, is bending a steel bar after heating it with the Mini-Ductor Venom HP. He did this to demonstrate to a customer that they could heat the steel bar and bend it to make custom display racks.

Have you used induction heat to shape, form, or create something new? We would love to hear about it! Contact [email protected] to let us know!

Contact Us

Have questions about induction heat? Reach out to us via phone at 877-688-9633 or email at [email protected].

Follow us on social media: Facebook • Instagram • LinkedIn • Twitter • YouTube