Your cart is currently empty!

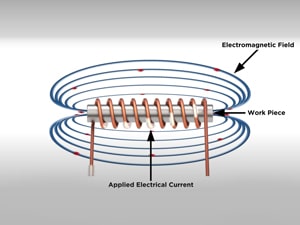

If you have recently purchased a tool from our Mini-Ductor® Product Line of powerful induction heaters, you know that each kit comes with a few induction heating coils. These coils are critical elements to the process of releasing seized parts, graphics, dents, moldings, and more; they also require a little knowledge to get started.

If you have recently purchased a tool from our Mini-Ductor® Product Line of powerful induction heaters, you know that each kit comes with a few induction heating coils. These coils are critical elements to the process of releasing seized parts, graphics, dents, moldings, and more; they also require a little knowledge to get started.

Our three basic coil variety pack comes standard with each Mini-Ductor kit. This package includes the 7/8” pre-formed coil, 41” Bearing Buddy®, and our 23” U-form, Shape-It-Yourself or DIY coil. All our induction heating coils are flexible and can be bent or separated to perform a variety of applications.

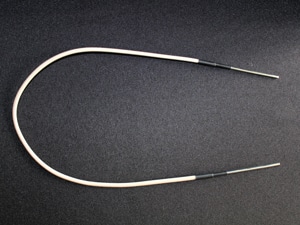

U-Form or Shape-It-Yourself Induction Heating Coil Molds to Your Application

The U-form coil is a straight heat-resistant flexible coil for do-it-yourself winding, which firmly holds its shape. This shape-it-yourself coil, made of Litz wire, is 23″ long and weighs 1.4 oz. The flexibility of this coil allows it to be wrapped to fit any application as long as you wrap the wire at least three times around the object being heated.

This coil can come in handy for various applications like heating O2 sensors, in-line applications, or in a space where a pre-formed coil will not easily fit.

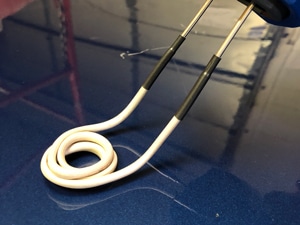

Removing Soft Dents with the U-Form Flexible Coil

One unique way to use this coil is to form it into what we call a “pancake coil.” A pancake coil can be used to heat the top of a flat surface. One application for the pancake shape is the removal of soft surface dents. To mold the pancake coil, you should first make sure that the wire is straight.

Then, wind the DIY coil three-quarters of the way down. You will want to wind each end two to three times as we mentioned. Having the coil wound three times will allow you to get the most optimum heating.

Once your coil is wound, plug it into your Mini-Ductor unit. Hold the flat coil about half an inch to an inch over the top of the dent. Heat in a small circular motion around the crown of the dent or the outside circle. As you move in a circular motion, gradually bring the coil closer to the dent. As soon as the dent shrinks, pull the U-form coil away and cool the treated area with a damp cloth.

Want a demonstration? Check out this soft dent removal video with our large dent removal tool, the Paintless Dent Repair (PDR) Baton. The process is the same.

Proper Coil Usage

All our coils should last for several hundred uses or more (subject to use). We recommend using the proper coil size, avoiding abrasion, and overheating prevents premature wear to the coil. Our coils are coated to eliminate oxidation, guarantee contact, and resist abrasion. However, if that insulation is breached, a new coil should be used. For more info on when to replace coils, check out our blog on How to Properly Use Induction Heating Coils.

Contact Us:

Use your u-form coil for something other than what we showed here? Make a video showing us how you use your u-form coil and tag us on social media using hashtag #InductionInnovations!

If you just purchased a tool with induction heating coils but are unsure of where to begin, contact an induction heating expert to help you select the perfect coil for your application! Or reach out with any questions.

Reach out to us via phone at 877-688-9633 or email at [email protected].

Follow us on social media: Facebook • Instagram • LinkedIn • TikTok • YouTube