-

March 14, 2025

March 14, 2025The Benefits of Buying American-Made Induction Innovations Products

When you choose American-made induction heating tools from Induction Innovations, you’re not… -

February 20, 2025

February 20, 2025Beginner’s Guide to Removing Auto Glass Like a Pro with the Glass Blaster Tool

Windshield—or “windscreen” removal, for our international colleagues—has long been a challenging process… -

April 16, 2024

April 16, 2024Induction Innovations NASCAR Sponsorship

All of us at Induction Innovations are thrilled to announce a partnership… -

November 29, 2023

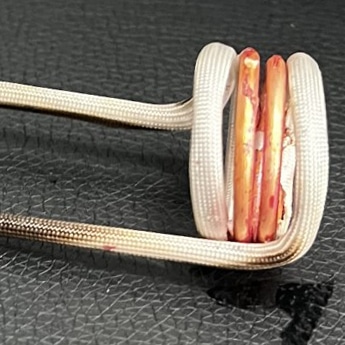

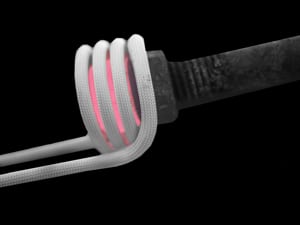

November 29, 2023Understanding Specialty Coil Packs vs Regular Coil Kits in Induction Heating

Induction heating, a process used in various industries for efficiency and precision,… -

October 18, 2023

October 18, 2023Pink Together, Stronger Forever

Induction Innovations is honored to sponsor and support Sadie Turner in the… -

September 8, 2023

September 8, 2023Induction Innovations: Turning Mechanics into Magicians!

Induction Innovations has been part of SEMA, the premier automotive trade show… -

August 31, 2023

August 31, 2023Precise Heating With Induction Heat!

What Metals Can Induction Heaters Be Used On? Induction heating has changed… -

June 19, 2023

June 19, 2023Heat Your Way into Summer: Induction Heating as a Safe and Reliable Solution

Summer is here! Finding the right heating tools, especially in warmer seasons… -

May 8, 2023

May 8, 2023The Benefits of Flameless Induction Heating for Marine Applications

Induction Innovations provides benefits in marine applications and offers a versatile method… -

March 27, 2023

March 27, 2023Induction Heating in the Agriculture Industry

Induction heating is quickly becoming a go-to solution for farmers looking to… -

February 23, 2023

February 23, 2023How to Care for Your Induction Heater

Induction heating units are an essential tool for many industries, including manufacturing,… -

February 9, 2023

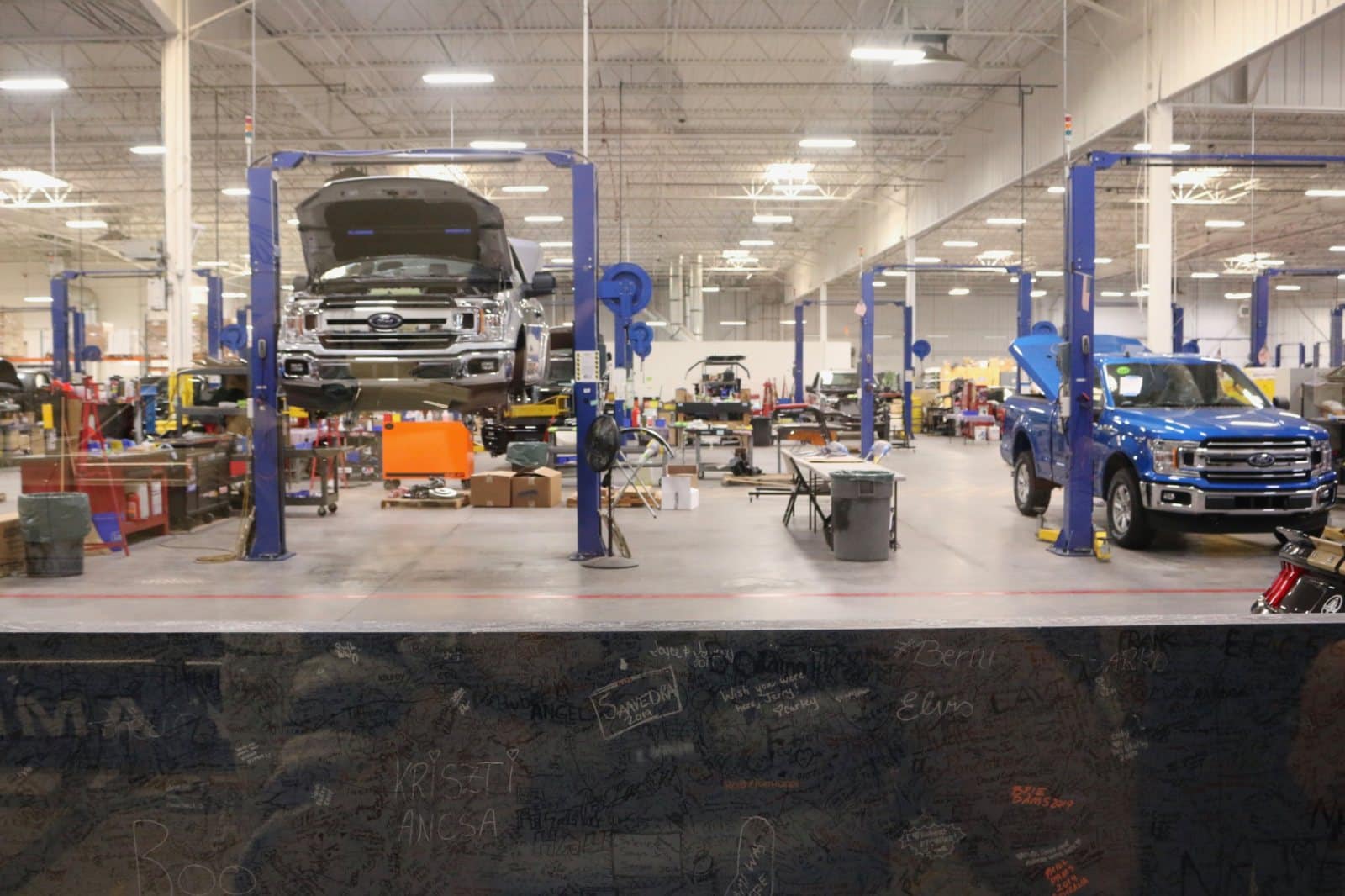

February 9, 2023Using Induction Heating in Auto Body Shops

Induction heating tools are used in auto body shops for heat treating,… -

January 3, 2023

January 3, 2023Put Down that Torch, Other Ways to Use Induction Heat

While industries across the board may differ in products, engineering, manufacturing practices,… -

December 1, 2022

Women in Auto Repair: How Female Mechanics are Changing the Automotive Industry

Ever wondered why every repair shop seems to be completely dominated by… -

September 30, 2022

September 30, 2022How You Can Support Breast Cancer Research with the Special Edition Mini-Ductor Pink Tool Kit

For any business, it is important to have the right tools at… -

August 5, 2022

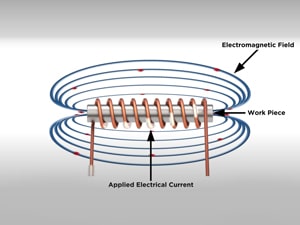

August 5, 2022How Induction Heating Technology Works (And Why You Should Know)

Induction heating technology has been around for 100s of years. In 2000,… -

July 22, 2022

July 22, 2022Why a Master Coil Kit is Essential for Any Induction Heating User

One of the most effective ways to optimize efficiency in any business… -

July 8, 2022

July 8, 2022How Induction Heat Provides Solutions Across Industries and Applications

If you are new to induction heat and Induction Innovations, you might… -

June 22, 2022

June 22, 20225 Reasons Why OSHA Regulations Have Led More Users to Switch to Induction Heat

The Occupational Safety and Health Administration (OSHA) is a regulatory agency tasked… -

May 27, 2022

May 27, 2022User Startup Guide

If you have recently purchased a new Inductor Series or Mini-Ductor Series… -

May 18, 2022

May 18, 2022Advantages of Induction Heating: 5 Benefits to Know

Induction heating is a safe, efficient, and sustainable method for heating ferrous… -

April 29, 2022

April 29, 2022How to Remove an Aluminum Panel off a Pickup Truck with Induction Heat

Did you know you can remove an aluminum panel off of a… -

April 21, 2022

April 21, 2022Induction Innovations Showcases Tools and Tips at 2022 Trade Shows

Induction Innovations is proud to have been a part of a wide… -

March 17, 2022

March 17, 2022Go Green with Induction Heat: Save Time and Money With Energy Efficient Products

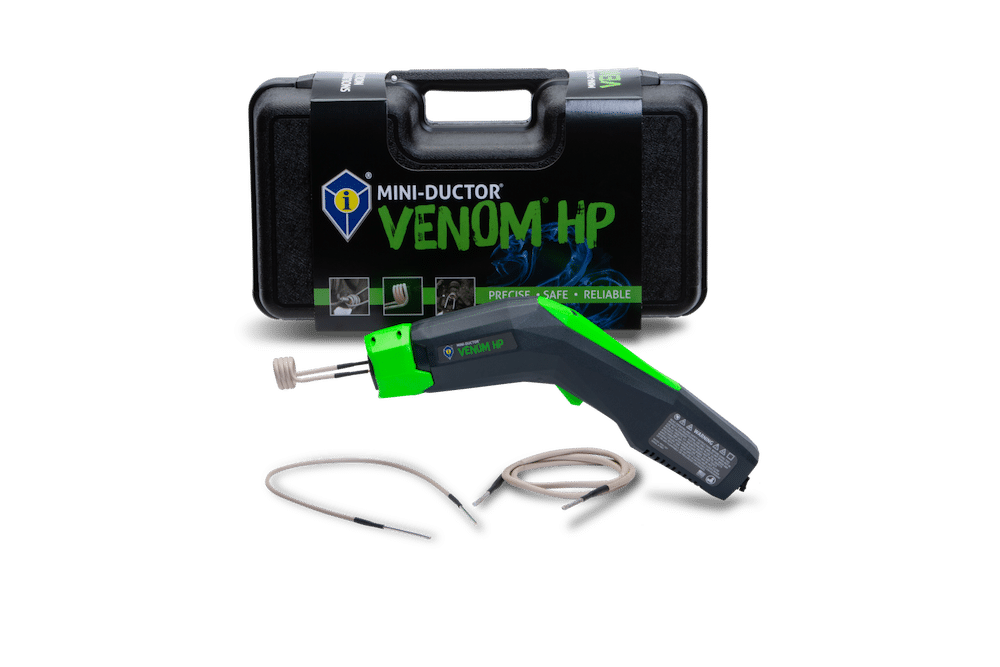

Go Green for St. Patrick’s Day Go green with the Mini-Ductor® Venom®…

1175 Jansen Farm Ct

Elgin, IL 60123

[email protected]

877.688.9633

Newsletter

This email list will keep you up to date with new product releases along with tips on product use.