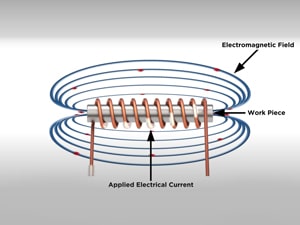

Induction heating is a safe, efficient, and sustainable method for heating ferrous metals and is used across various industries. Induction heat has minimal wasted heat, with a direct transfer of energy to the part being heated. There are numerous advantages of induction heating when compared with traditional methods such as an open flame, from practical upgrades to those that better protect our environment.

Induction heating is a safe, efficient, and sustainable method for heating ferrous metals and is used across various industries. Induction heat has minimal wasted heat, with a direct transfer of energy to the part being heated. There are numerous advantages of induction heating when compared with traditional methods such as an open flame, from practical upgrades to those that better protect our environment.

We believe in providing solutions that enable shops and technicians to tackle their everyday challenges, to return a better profit, and help prevent unnecessary injuries, damage, and repairs.

Let us look at why you should choose induction heating for your application, including five main benefits!

Why is an Induction Heater the Best Choice?

Induction Heating Advantages:

1. Quality Precision

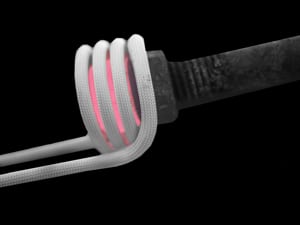

With the ability to fit into tight spaces or difficult angles and to centralize your heat source, you can provide constant, local contact. One of the questions we get asked is whether induction heating is more efficient than other heating methods. The short answer is yes! This heat is consistent and covers the entirety of your part or application source. With induction heat, you are able to avoid uneven heating and inconsistent results that are common with an oxy-acetylene gas torch.

2. Reduced Cost

There are many ways that induction heating removes unnecessary costs and saves energy. When using a gas torch, customers can pay $35-$175 to replace gas tanks as well as servicing costs. With induction heat, you only need to pay for replacement coils, which last over 200 uses and are less expensive (individual coils range from $13-$52.50).

You can also salvage parts that would otherwise be discarded because induction heat does not damage the metals. Additionally, induction heating users save more on insurance, on average 10-30%.

3. Reduced Damage & Injury Risk

Induction heat produces localized heat which focuses on one part, not a larger area you would get with a torch. This targeted heat reduces collateral damage to adjacent parts or plastic. It also removes the risk of igniting flammable material that can lead to property damage. Induction heat also reduces the risk of injury (such as burns) and damage to your tools.

Learn more about damage and risk reduction on our induction heat vs. torch comparison page.

4. Increased Productivity and Process Efficiency

You can immediately begin using induction heat in the workplace to improve quality and yield better performance because our products are easy to use. The Mini-Ductor® series can loosen ferrous hardware in just a matter of seconds. The Venom and Venom HP‘s angled designs reach tight spaces. You also will not have to remove or cover other flammable or combustible materials because there is no open flame.

5. “Green” Technology

Unlike traditional torches that can pollute the environment by burning fossil fuels, induction heating is free of hazardous emissions. It reduces and often removes the need for harmful solvents. Additionally, induction heating tools are more energy efficient. You do not have to worry about cleaning up spilled gas or solvents. Learn more about going green with induction heat!

Contact Us:

Since 2000 Induction Innovations, Inc. has helped customers enjoy the advantages of turning to induction heat for their project applications to save time, resources, and money.

Talk with us about your needs and secure the perfect product for your requirements. Reach out to us via phone at 877-688-9633 or email at [email protected].

Follow us on social media: Facebook • Instagram • LinkedIn • TikTok • YouTube