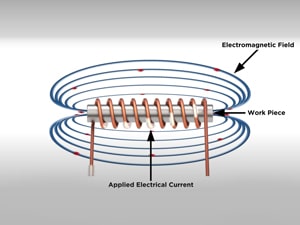

Induction heating units are an essential tool for many industries, including manufacturing, autobody shops, marine repair, heavy duty, agriculture and more. These units use an electromagnetic field to heat ferrous metal components, making them ideal for a wide range of applications. However, like any other tool or machine, induction heating units require proper care and maintenance to ensure they continue to perform at their best. In this blog post, we’ll cover the basics of induction heating unit care, what to check, including coils, attachments, and heating times and their importance.

Basic Care of Your Induction Heater

Basic care is essential to keeping your induction heating unit in good working order. Inspecting the unit as a well as the work coils for any signs of wear or damage, and ensuring it functions properly. In addition, check the ground fault interrupter (GFI), attachments, and ensure that the unit is always stored properly and kept dry.

When using the Mini-Ductor® Venom and the Mini-Ductor Venom HP, check the fault LED light before use. Ensure the thumbscrews are tightened correctly on your Mini-Ductor® II unit. On the Inductor® series, make sure to check the bellows and hose as well as checking the thermal tape on the attachments. Lastly, it’s always a good idea to check the power supplies and make sure the unit is properly grounded.

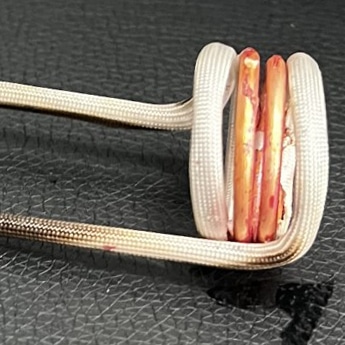

Check the Coils

The coils in an induction heater play a crucial role in heating metal components. Regularly checking the coils is essential to ensuring that your unit is functioning properly as well ensure the unit lasts longer.

- Inspect coils for signs of damage or wear, such as fraying or cracks and replace if necessary

- Check connections to make sure they’re secure

- Make sure the coil is inserted into the unit correctly

- Ensure coils are functioning properly by testing the unit

Regularly check the coils to ensure they’re in good working order and to prevent any potential problems in the future.

Importance of Checking Attachments

The attachments in an induction heating unit are just as important as the coils. They help to align the metal components and ensure they’re heated evenly. Regularly checking the attachments is essential to ensure they’re properly aligned and securely fastened. If you notice any signs of wear or damage, it’s time to replace the attachments.

- Ensure the thermal tape is still intact. If not, do not use the attachment, as metal-on-metal contact is one of the most harmful things for your unit. If you have any questions, give us a call!

The Importance of Heating Times

The heating time in an induction heating unit is critical to its performance. The metal components won’t be heated evenly if the heating time is too short. If the heating time is too long, it can cause damage to the unit and the metal components. Regularly monitoring the heating time is essential to ensuring that your induction heating unit works properly. You just want to heat the application to the point that it is smoking not glowing. Redder is not better. If the bond or application you are working on does not release, repeat the process based on the timing below.

For example, the Mini-Ductor® Venom and Mini-Ductor® II should be used no more than 15 secs consecutively, allowing for the transference of heat into the application.

The Mini-Ductor® Venom HP should be used on an application for 5-7 seconds.

The Venom HP is the latest evolution of portable induction heaters from our Mini-Ductor series. It uses 1800 watts compared to 1000 watts on our older models. What this means is that it heats 80% faster than our older units. This does not translate that it gets hotter, just the speed that the unit heats applications. This series has multiple models for use in automotive, construction, industrial, and marine industries. Contact us to learn more about any of our Mini-Ductor models.

Keep Your Induction Heater Performing at its Best

Induction heating units are an essential tool for many, and like any tool in your shop or garage require proper care and maintenance to keep at is best. However, you may be doing all the necessary steps for your unit and still find it not working properly. If that’s the case, call us at 1-877-688-9633 or visit our website and check out our Support Page.

Take the time to properly care for your induction heater, and you’ll be rewarded with reliable and effective performance for years to come.