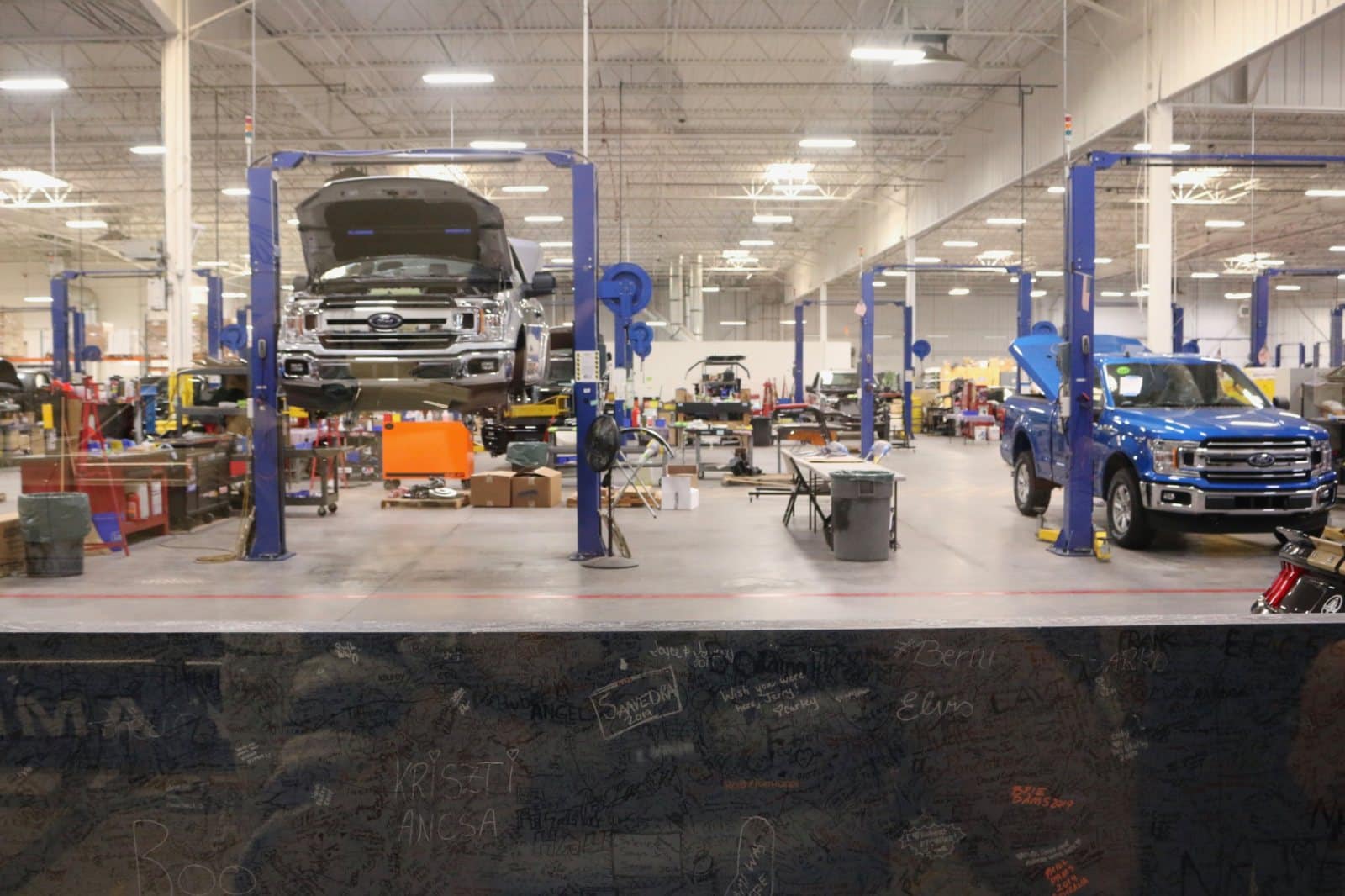

Induction heating tools are used in auto body shops for heat treating, soldering, preheating for welding, shrink fitting, glass removal, curing, de-bonding, and many other applications. Induction heating applications and methods are used in agricultural and farming, boat and marine repair, trucking and heavy-duty equipment, and other industries. Induction heating tools are well-suited to auto body shops, making the most of your shop investment.

In this blog post, we’ll briefly discuss what induction is, how it works, what an induction heating system is, safety concerns, best uses, and more. You’ll soon discover why you should use induction heating in your shop and the advantages of using induction over other types of heat sources.

What is Induction Heating

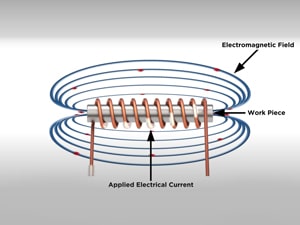

Induction heating is a method of heating electrically conductive materials (steel, aluminum, brass, copper, gold, platinum, etc.) and semiconducting materials (germanium and silicon). Induction heating is a contactless method of heating conductive and semi-conductive materials, and it is very fast and efficient. The Inductor® Pro-Max is a heavy-duty induction heating system that can be a workhorse in your auto body shop. The Inductor® series gives you a variety of attachments to meet many auto repair needs.

Advantages of Using Induction Heating in Auto Body Shops

Induction heating has important advantages over flame or spark welding.

- No need for a flame or spark means the risk of fire is eliminated, along with the possibility of fumes and sparks damaging nearby equipment and causing injuries.

- In addition to being safer, induction heating can heat metal much faster than burning it. This is because you are using a direct current to create an electromagnetic field that heats up the metal by exciting the molecules of the application.

- Finally, induction heating can only be used on any ferrous metals.

The induction heating process is used in many ways in the automotive industry.

It is also used for:

- Soft dent removal

- Windshield and auto glass removal

- Removal of decals, vinyl graphics

- Door skin removal

- Seam sealer removal

- Recessed lug nuts

- Removal of spray on bed liners

Versatile Induction Heating Systems

Induction heating, also known as inductor heating or magnetic induction, is a fast and efficient way to heat metal and is a favored method in auto body shops. It uses a coil of wire that generates heat when placed in a magnetic field. The process takes place at high temperatures and makes it possible to heat materials quickly and uniformly.

Induction heating can be used for many different applications in a body shop, including:

- Heating steel for welding seams and spot repair work.

- Removing seized wheels or other parts.

- Heating brake drums or disc brakes before replacement to prevent warping during removal and installation processes (the braking system relies on the metal being able to expand with use).

The high temperature produced by induction heating makes it ideal for numerous other tasks that require intensive heating, like bending sheet metal into custom shapes or creating custom gaskets for engines and transmissions (whereas traditional methods would take much longer if at all possible).

Are Induction Heating Systems Safe?

Induction heating systems are safe and easy to use in an auto body shop or other work areas. They use no open flames or sparks, so there are no fire hazards in your autobody shop. You also don’t need to worry about dangerous fumes like carbon monoxide—induction heating creates its own energy source, so the induction heater doesn’t produce any gases.

Improving Efficiency in Auto Body Shops with Induction Heating

An induction heater heats metal parts in a fraction of the time that other methods would, allowing you to work more efficiently and spend less time on projects. Induction tools are also easy to use, saving your team valuable time that can be used on the auto shop floor rather than through lengthy training.

Induction tools are safe for both your employees and the environment. Instead of using an open flame or an acetylene torch, these machines create electromagnetic fields that transfer heat directly into metal parts without risk of ignition or fire damage. Induction heaters are also cost-effective since they don’t need additional equipment, such as compressed air lines or gas tanks, that traditional welding devices need.

Benefits of Induction Heaters for Auto Body Shops

Induction heating tools can save time, increase profits, and improve safety.

Reduced need for multiple tools, multiple employees, and workstations. In an environment where every tool is being used at once by different employees at different stations, it’s hard to justify buying a new tool if you don’t have the space or manpower to use it effectively.

The same goes for having separate workstations; if one employee can use the induction welder on one side of the shop and another might want to use a MIG welder on another side of the shop, then you will need two workstations just so each person can perform his job more efficiently.

The Mini-Ductor series is less expensive than other methods, and it reduces crowded workspace conditions without sacrificing quality results from your repairs—a win-win situation.

Shared Auto Body Shops

Shared auto body shops can benefit from induction heating tools, as they allow for versatility and cost efficiency. Induction heaters are a good investment because they offer many benefits and make it easier for you to complete tasks such as:

- Body side moldings

- Removing tight bolts

- Welding structural steel and other metals

- Bend and shape pipe and tubing

Add Induction Heating to Your Auto Body Shop

Induction heating is an efficient and affordable way to keep your auto body shop running smoothly. You’ll get repairs done quickly, support green technology, and enhance safety throughout your shop while increasing your productivity. For over 20 years, Induction Innovations has been a leader in induction heating technology. Contact us today, and we can connect you with the perfect Inductor® line of equipment, tools, and accessories. Call us at 877-688-9633 or email at [email protected].