Induction Innovations NASCAR Sponsorship

Induction Innovations: The Choice of ASE Master Technicians & Modern Repair Operations, Worldwide.

Learn why induction heating is better, faster and safer than oxy-acetylene torches for removing seized nuts, bolts, other fasteners, bearings, and more.

Learn how induction heating is used on cars, trucks, farming equipment, boats, excavators, forklifts, scissor lifts, scales, CNC machines, and more.

Learn how induction heating heats metal red hot in seconds without hand injuries, burning parts, broken breaker bars, and busted torque bits.

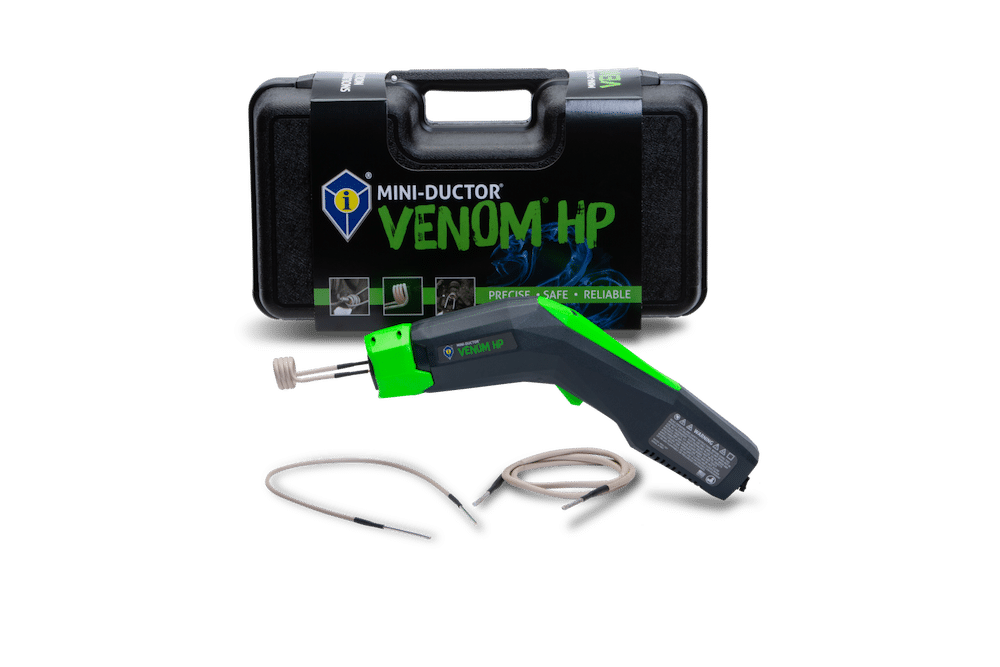

Our hand-held inductor is ideal for removing seized nuts, bolts, bearings, tie rods, other fasteners, and oxygen sensors.

Learn MoreThe Inductor Series is ideal for removing windshields, other glass, trim, chrome, panels, bedliners, dents, and large fasteners.

Learn More

Hello. Thank you for your interest in the Inductor® line of products. This email list will keep you up to date with new product releases along with tips on product use. We do not solicit product or share your information from joining this list.