Induction Innovations NASCAR Sponsorship

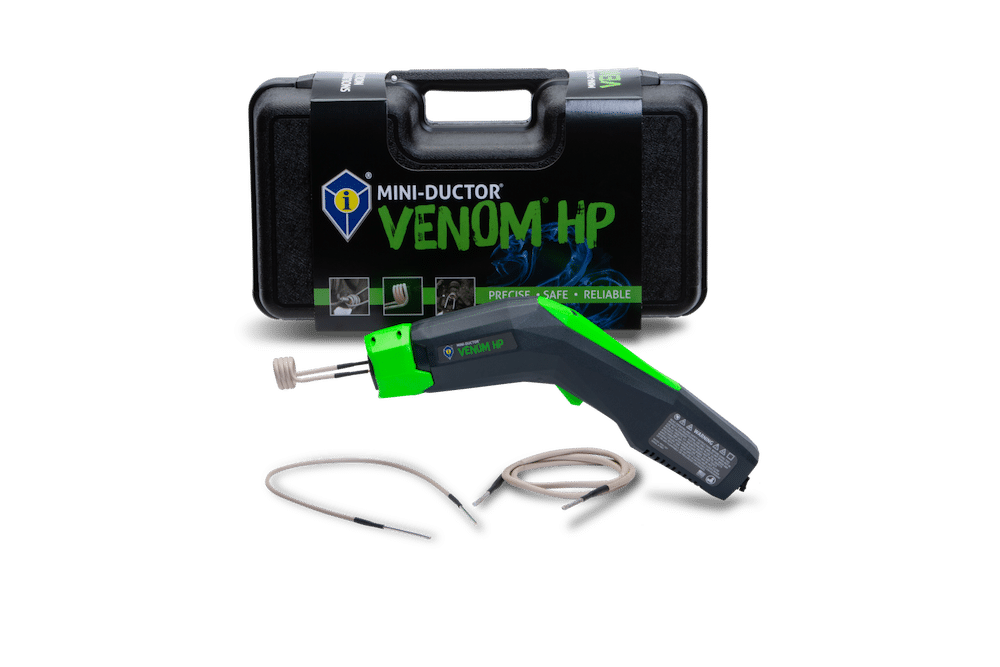

All of us at Induction Innovations are thrilled to announce a partnership with Thad Moffitt, who will debut his full-season NASCAR Craftsman Truck Series in 2024 with Faction46. We are thankful for the opportunity that Thad and Petty’s Garage have provided us, and we are thrilled to see Thad as he hits the track and […]

Read More